I've almost certainly forgotten something, so feel free to email me for clarification (or if you want me to build you something): construct@jaxter184.net

Build guide

Laser cut 3mm clear acrylic

- Export the laser cutting files from

06-panel.FCStd- Select the

Pagein the tree view - File -> Export (Ctrl+E)

- Filetype: Technical Drawing (*.svg)

- Save

- Select the

- Might need to be manually cleaned up

- 6 pieces

- Thanks to the friends who let me borrow their laser cutter

One-way tint film

- This particular product was shipped without a cardboard roll, or any outside protection, so there were some scuffs and wrinkles

- Is often adhesive backed, even if it doesn't seem like it

- Spritz down some water while applying, it makes bubbles easier to move, and doesn't affect the adhesive as far as I can tell

- Apply to acrylic a bit too large, then cut away the excess

- The holes are a little weird, but you can just roughly cut inside them with a craft knife

3D-printed corner brackets

- Export from

06-corner.FCStd - Print with the inner side down, outer corner facing up

- Get the ethernet hole version by setting the tip to

Pocket008(in the treeview right click menu asSet tip) - May need to use a drill to clean up the holes depending on your printer

- I used PETG, but most "regular" materials are probably fine

Bits and bobs

- Ethernet keystone jack

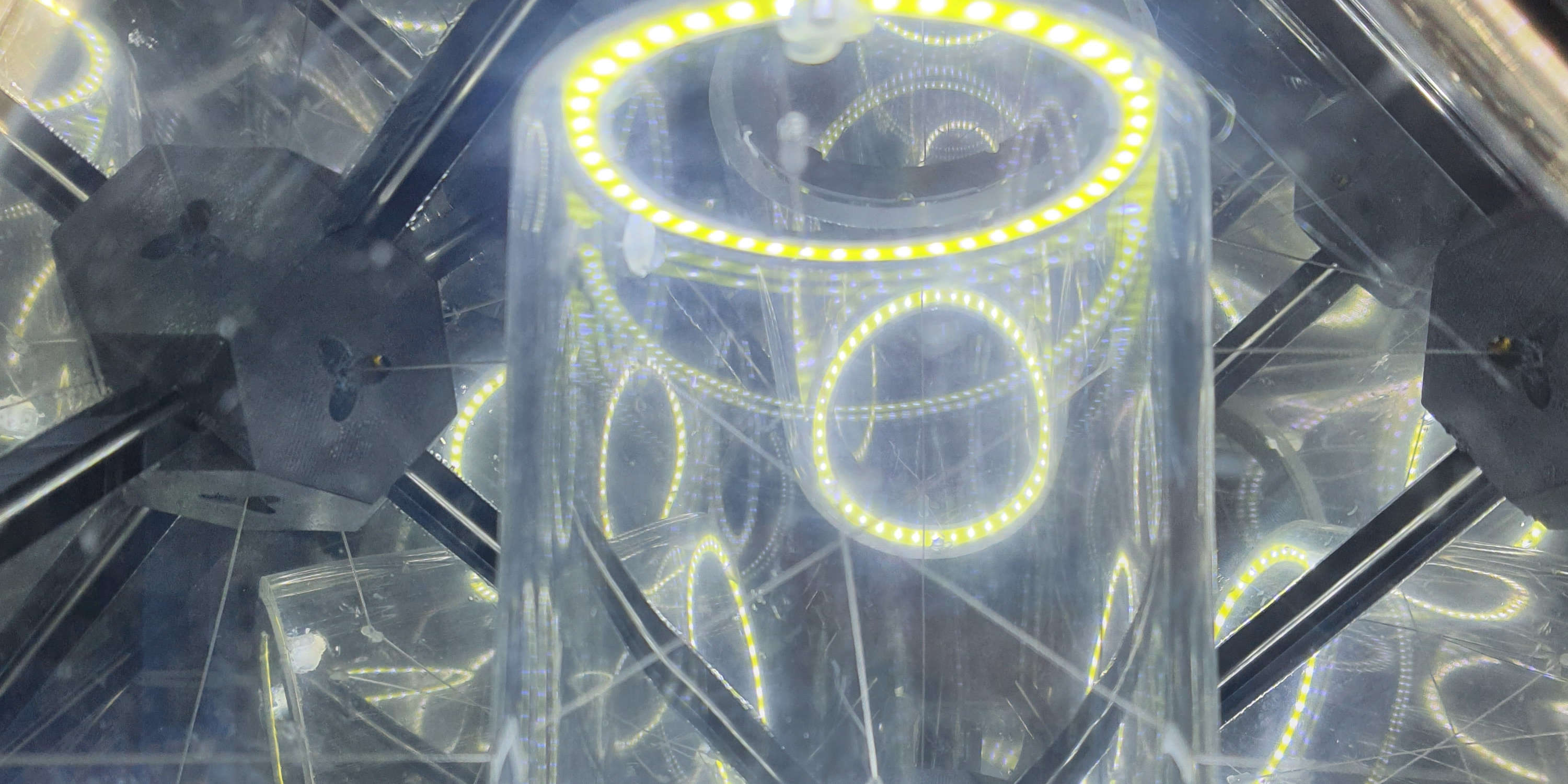

- LED Ring (80mm outer diameter)

- T Plates

- M3*8mm machine screws (to attach panels to corners)

- M5*8mm machine screws (for aluminum extrusion)

- M3 eye bolts

- M3*OD5mm*6mm Heat-set inserts

- M3 and M5 Slot T-nuts

- 2mm*125mm Steel rods

- ID80mm*100mm Acrylic tube

- TODO: drilling procedure

- 0.5mm cable

- Cable clamps (I just bought the smallest ones I could find)

- I also used crimp-style ones, but they require a special tool, so if you're just doing a one-off, it's probably better to just use the screw-style ones

- Aluminum extrusion

- TODO: lengths

TODO: document electrical crimes